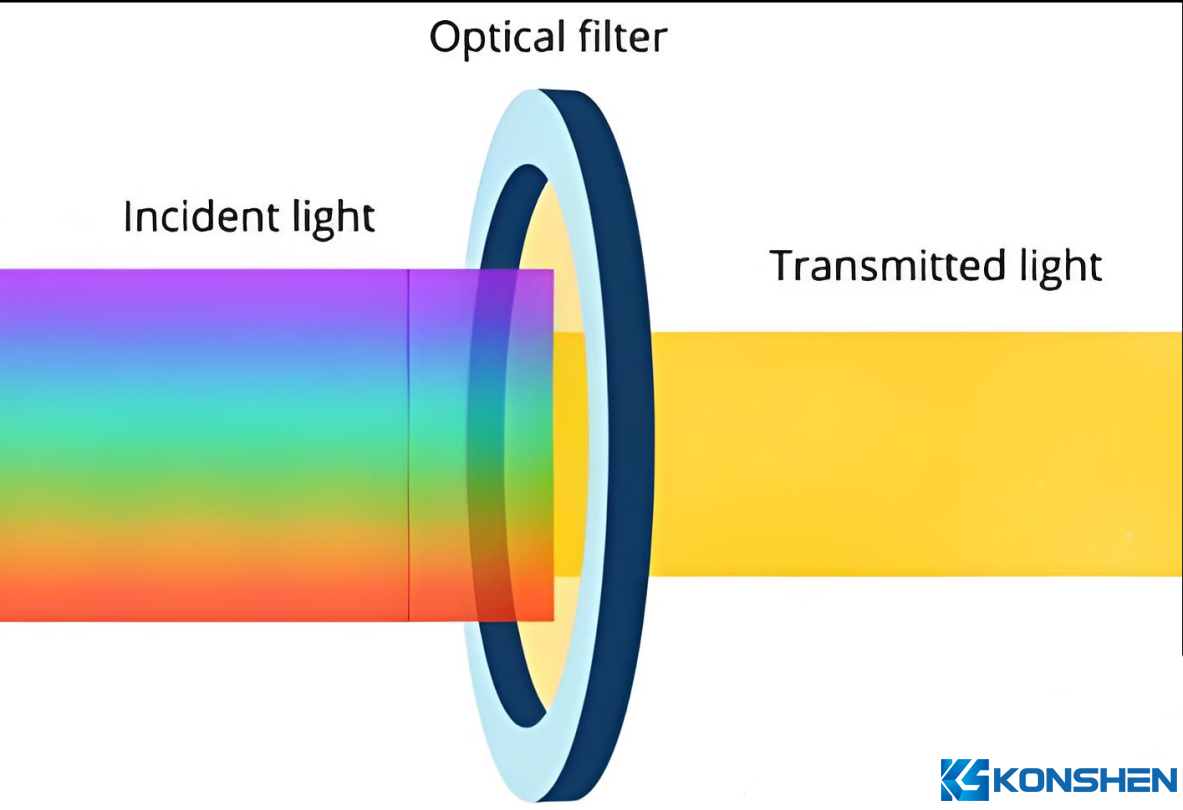

In modern optical systems, even the smallest imperfection—a single micron—can make a measurable difference. Whether it is a lens used in medical imaging, a filter embedded in a semiconductor lithography machine or a sensor designed for aerospace navigation the overall performance is highly dependent on the precision of the surface finish. Surface finish refers to the microscopic condition of the light-transmitting areas including allowable scratches digs and roughness that exist on the optical filter surface.

Overlooking surface finish isn't just a cosmetic issue—it can undermine the entire system's performance. It directly influences transmission efficiency image clarity and the long-term reliability of the entire optical system. Surfaces that are poorly finished cause increased light scattering spectral distortions and premature degradation. These issues can lead to costly downtime expensive replacements and diminished system performance.

As optical technologies move toward smaller footprints, faster speeds, and higher resolutions, the role of surface finish becomes even more critical.This article dives into what surface finish means how it is measured why it matters and the ways it impacts the lifespan and efficiency of optical filters. It also touches on emerging trends shaping the future of optical finishing technology.

Surface finish describes the microscopic quality of a filter's active optical area. It defines the size depth and distribution of tiny imperfections such as scratches pits or particulate contamination. These standards ensure light travels through with minimal distortion or energy loss, protecting both the filter’s optical integrity and long-term durability.In practical terms surface finish determines several critical performance factors:

Light scatter levels: A smoother surface reduces stray light improving image contrast and sharpness.

Spectral accuracy: High-quality finishes are essential in systems requiring precise wavelength transmission for imaging or sensing.

Durability under environmental stress: Well-finished surfaces resist abrasion coating delamination and degradation under challenging conditions.

Maintaining superior surface finish is fundamental to achieving peak optical performance and extending component lifespan.

Scratch-Dig Specifications and Surface Roughness (Ra) are both key indicators for evaluating optical filter quality and manufacturing precision. Here’s what they mean:

One of the most widely accepted benchmarks for optical surface finish is the MIL-PRF-13830B standard. It uses the scratch-dig classification system to define maximum allowable defect sizes.

For example,a 60-40 specification permits scratches up to 60 μm wide and digs up to 40 μm in diameter.

Stricter requirements, such as 40-20, apply to high-power laser optics or precision imaging systems.

The first number specifies the maximum scratch width; the second, the largest dig diameter. The standard also limits the cumulative defect area per inspection zone to ensure overall quality.

Optical performance: Tighter scratch-dig values translate to reduced scattering, higher image contrast, and stronger signal fidelity.

System reliability: Especially in laser applications scratches can cause localized heating leading to coating damage or catastrophic failure.

|

Scratch-Dig Spec. |

Quality |

Application |

|

80-50 |

Very Low |

Acceptable quality, can be easily fabricated |

|

60-40 |

Low |

Commercial quality, used for non-critical low power laser and imaging applications, where scattered light is not as important as cost. |

|

40-20 |

Morderte |

Standard scientific research applications for low to moderate power laser or imaging, which tolerate little scattered light. |

|

20-10 |

High |

Precision quality, minimum standard for laser mirrors and extra-cavity optics used in moderate to high power laser. Minimizing scattered light. |

|

10-5 |

Super High |

High precision quality, used for the most demanding applications such as intra-cavity laser optics or high power applications. |

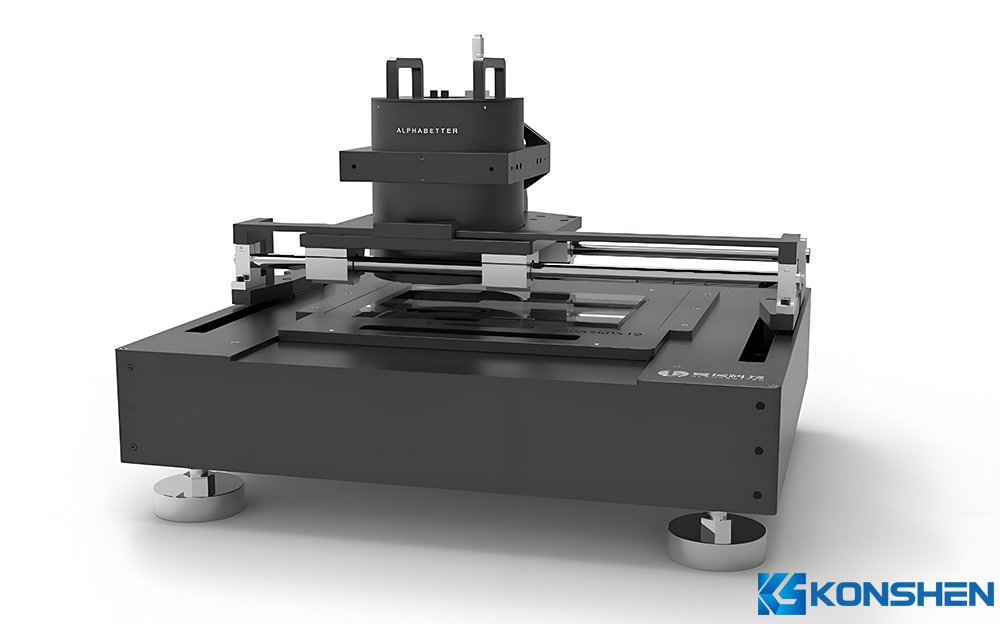

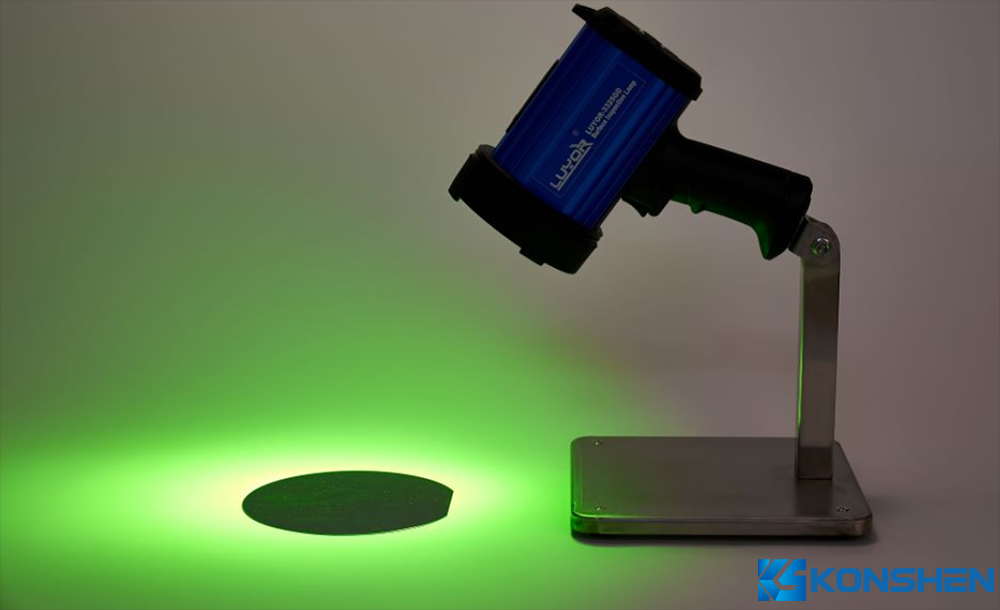

Traditionally, inspectors compared surfaces visually under controlled lighting using reference plates. Today, advanced tools like interferometers and laser scatter analyzers provide sub-micron accuracy—crucial for aerospace, semiconductor, and other high-tech fields where defects can't be tolerated.

Surface roughness (Ra) quantifies the average deviation from an ideal flat plane, usually measured in nanometers. High-end optics often require Ra values below 1 nm to minimize diffuse scattering and maintain clarity.

Lower Ra values reduce diffuse scattering which enhances light transmission and image clarity.

Higher Ra values introduce optical noise and lower the signal-to-noise ratio, leading to errors in high-precision measurements and imaging.

The impact of surface finish goes beyond just optical clarity. It significantly affects how long filters and optical components last under real-world operating conditions. Filters manufactured to MIL-PRF-13830B or equivalent standards can reliably function for over 10,000 hours without performance degradation even when exposed to ultraviolet light temperature fluctuations and humidity.

Conversely surfaces with poor finish quality accelerate coating failure increase cleaning requirements and reduce overall system uptime. In semiconductor fabrication facilities these problems lead to costly production delays and lost output measured in millions of dollars.

Maintaining superior surface finish thus plays a direct role in maximizing the operational efficiency and lifespan of optical filters across a variety of demanding industries.

|

4.1 Medical Imaging and DiagnosticsDevices such as endoscopes surgical navigation systems and fluorescence imaging tools demand optical filters with near-perfect surface finishes. This ensures highly accurate distortion-free visualization which is crucial for patient safety and effective diagnosis during medical procedures. |

|

4.2 Aerospace and DefenseOptical systems used in satellites defense-grade sensors and space exploration equipment operate in harsh radiation-rich and thermally extreme environments. Only filters with stringent scratch-dig ratings like 40-20 and surface roughness below 1 nanometer can deliver stable performance and long-term reliability. |

|

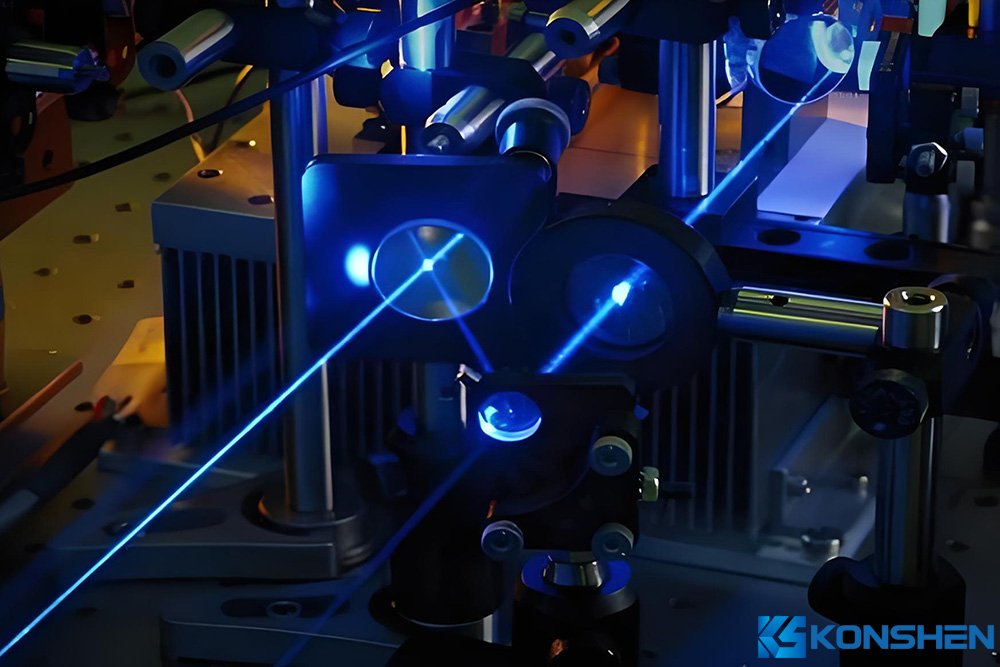

4.3 Industrial Lasers and Semiconductor EquipmentLaser cutting systems wafer lithography machines and precision metrology tools require ultra-smooth optical components. Even tiny surface imperfections cause beam distortion energy loss or catastrophic failure. Hence these industries demand finishes with sub-nanometer roughness and extremely low defect densities. |

|

4.4 AR/VR and Consumer ElectronicsEmerging augmented reality virtual reality and other consumer technologies rely on ultra-thin flawless optical filters. Besides clarity these devices need fingerprint resistance and haze reduction to maintain immersive user experiences and long product lifetimes. |

Surface finish isn't just a technical specification—it's a performance-defining factor that governs clarity, durability, and reliability across multiple industries. From meeting strict scratch-dig standards to achieving nanometer-level surface roughness every specification counts toward ensuring optimal filter function and lifespan.

In sectors where precision and longevity are non-negotiable including medical aerospace semiconductor and advanced consumer electronics choosing the right surface finish can make all the difference.

Contact KS Glass today to explore tailored solutions designed to elevate your optical system performance.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us